In welded joints, it is the weld that most often becomes a critical element where stresses are concentrated, fatigue failure occurs and failures occur. Practice shows that when welding fails, the entire structure is often destroyed.

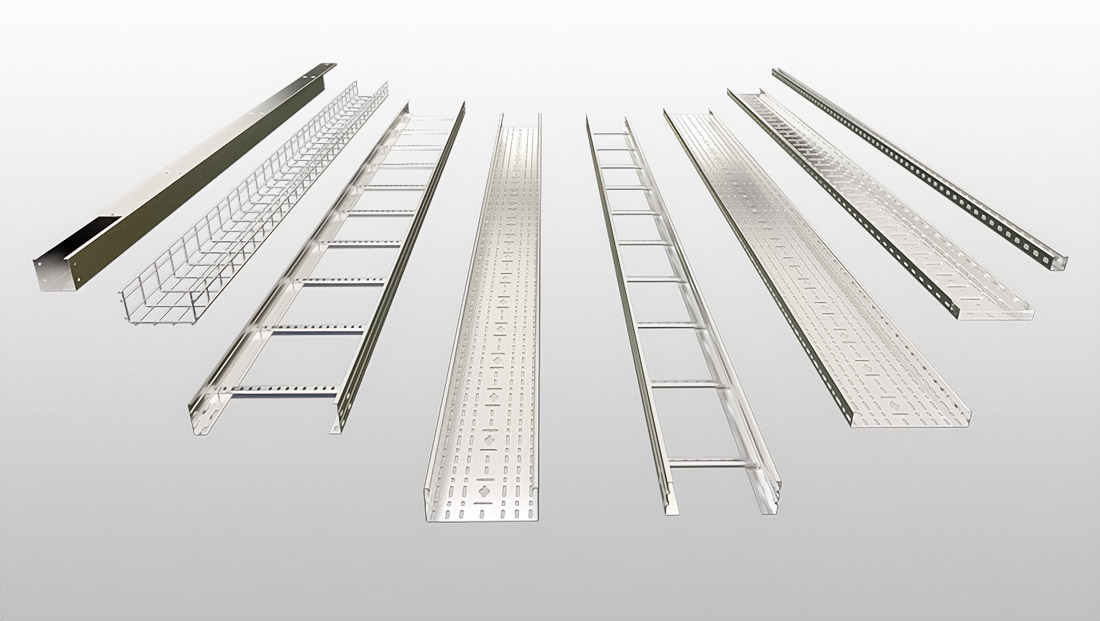

This is especially relevant for cable support systems such as wire mesh tray installations, where real operating conditions involve dynamic loads, vibration, thermal expansion, and long-term fatigue rather than static load ratings alone.

Over more than 60 years of research and practical experience in the field of welding, a stable understanding has been formed of what parameters determine a high-quality weld and why welding quality control is an essential element of safe production.

Joint Strength and Full Penetration

The basis of a high-quality welded joint is complete penetration. This means that the seam metal completely merges with the base material over the entire design thickness. Insufficient penetration or non-welding forms hidden weak zones that become stress concentrators. Under the influence of mechanical loads, vibrations and cyclic loading, such zones quickly enter the stage of fatigue failure.

Practical inspections of welded structures show that, in the absence of proper control, up to 60% of butt joints may contain defects in the seam root, including non-welding. This directly reduces the strength of the joint and operational reliability.

Seam Geometry and Stress Distribution

The geometry of the weld plays a key role in stress distribution. Sudden transitions, undercuts, excessive reinforcement of the seam or an incorrect profile create local areas of increased stress. It is in these places that fatigue cracks are most often initiated.

Even in the absence of internal defects, the irregular shape of the seam can significantly reduce the fatigue strength of the structure. This is particularly critical for suspended cable systems and wire mesh tray supports, where continuous vibration and variable loading are common. As a result, requirements for weld geometry include controlled reinforcement, smooth transitions to the base metal, and the complete absence of undercuts.

Typical Welding Flaws and Their Impact

The most dangerous welding defects are:

- Cracks

- Non-steam and lack of fusion

- Undercuts

- Significant misalignment of the elements

Less critical, but still undesirable, are porosity and non-metallic inclusions. The main danger of critical defects lies in their shape: the sharp edges of the defects increase stress concentration and accelerate the development of destruction.

Heat Investment and Deformation

Welding is inevitably associated with local heat input. Excessive heat input leads to deformations, residual stresses, and changes in the structure of the thermal impact zone. Deformations can affect not only the appearance of the product but also its strength, rigidity, and assembly accuracy.

The minimisation of deformations is achieved due to the correct choice of welding parameters, the sequence of suturing and the use of devices for fixing the elements. It is important to understand that deformation accompanies even high-quality welds and should be considered as a technological factor, not just a defect.

Quality Control and Non-Destructive Methods

Welding quality cannot be ensured without system control. A typical set of methods includes visual inspection, methods for detecting surface defects, and methods for detecting internal defects such as radiography and ultrasound.

Mechanical tests are also used to qualify welding procedures, making it possible to assess tensile strength, ductility and impact strength. In some cases, impact strength tests are carried out at temperatures up to -40°C, which is especially important for structures operating at low temperatures.

Welding Procedures and Qualifications

The welding procedure is a regulated set of parameters: welding current, voltage, welding speed, heat input, joint type and edge preparation. These parameters are selected and confirmed during the qualification tests.

The qualification of a welder is closely related to the qualification of the welding procedure. Even an approved procedure does not guarantee quality without observing the parameters in practice. Deviations from the set mode often cause defects, even if the correct technology is formally used.

Electrical Parameters and their Effect on Seam Quality

The stability of the arc directly depends on the electrical parameters of the welding process. Welding current, voltage, circuit resistance and voltage drop have a direct effect on the formation of the seam.

Excessive voltage drop, usually exceeding 2-3%, leads to unstable arcing, metal splashing and uneven melting. This is especially important when using long welding chains and cables with insufficient cross-sections.

The Role of Welding Cables and Thermal Load

Welding cables are part of the electrical circuit and affect the stability of the welding process. The conductor’s cross-section, flexibility, resistance, and ability to dissipate heat determine how efficiently energy reaches the arc.

Overheating of the cable not only reduces the efficiency of current transmission but also increases the risk of insulation damage, which is directly related to safety. The welding duty cycle is usually calculated in the range of 10 minutes, and it is in this mode that the thermal load on the cable and equipment is estimated.

Automation and Monitoring of Welding

Mechanised and automated welding can improve repeatability and quality stability. Laser welding and hybrid processes combine high speed with low heat input, which reduces deformations.

Seam tracking and process monitoring systems in real time allow you to adjust the position of the tool and welding parameters, compensating for deviations in the joint geometry. This reduces the number of defects and the amount of subsequent repairs.

Welding Repair and Serviceability Assessment

Repairing welds is an expensive operation. Practice shows that the cost of correcting defects can exceed the cost of primary welding by up to 10 times. At the same time, re-welding itself is an additional source of heat investment and stress.

In some cases, a serviceability assessment based on strength calculations and fracture mechanics is used. This approach allows you to determine whether the identified defect is acceptable from the point of view of the actual load, without immediate repair.

Fatigue Strength and Improvement Methods

Fatigue cracks most often originate in the seam transition zone to the base metal. Improved fatigue performance is achieved by removing sharp stress concentrators. Grinding the reinforcement of the seam and smoothing the transitions can increase the fatigue strength class.

At the same time, the depth of material removal is strictly limited: it is usually about 0.5–0.8 mm so as not to reduce the estimated thickness of the element.

Welding quality is a combination of factors: from the correct choice of welding parameters and control of heat input to the electrical characteristics of the welding circuit and the qualifications of personnel. A durable weld is not the result of one successful pass but the result of a systematic approach that includes quality control, defect analysis, and an understanding of stress distribution and operating conditions.

For cable support systems supplied by cable tray suppliers in Dubai long-term performance depends far more on weld quality than on nominal load ratings alone. Ignoring welding quality leads to reduced reliability, increased repair costs, and a higher risk of structural failure. That is why welding quality remains a fundamental element of engineering responsibility and technical safety.

I serve as a financial expert on the Today Show and Good Morning, America. I like to give reasonable advice on budgeting to people with any income level.